Call Now: +91-9825344828

Wall Putty Plant

Specification

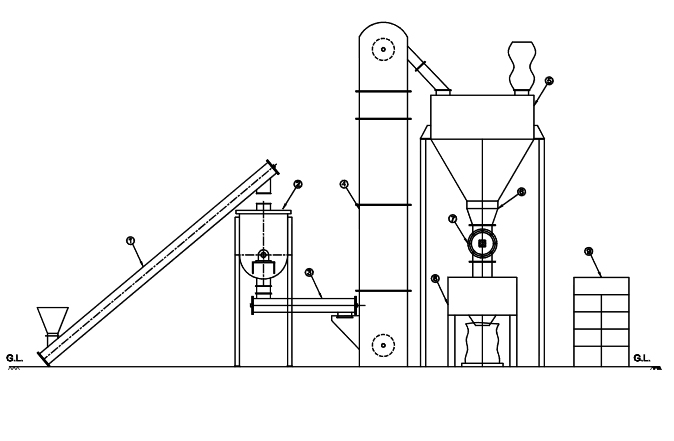

Fully Automatic Wall Putty Making Plant Heaving Following Machines :

1. Feeding Screw Conveyor

2. Ribbon Mixer

3. Discharge Screw Conveyor

4. Bucket Elevator

5. Storage Silo

6. Vibrating System

7. Rotary Air Lock Valve

8. Packing Machine

9. Electrical Panel

In This Plant We Have

Following Capacity Machines

1000 Kg, 2000 Kg, 3000 Kg, 5000 Kg, Per Hour

1. Feeding Screw Conveyor

2. Ribbon Mixer

3. Discharge Screw Conveyor

4. Bucket Elevator

5. Storage Silo

6. Vibrating System

7. Rotary Air Lock Valve

8. Packing Machine

9. Electrical Panel

In This Plant We Have

Following Capacity Machines

1000 Kg, 2000 Kg, 3000 Kg, 5000 Kg, Per Hour

Wall Putty Plant are extremely flexible tools and are perfect for paint, ink, pharmaceutical and other building chemicals manufacturing. This device guarantees that agglomerates are properly broken and can also blend different kinds of liquid to obtain good value yield.

Features of Wall Putty Plant Exporter:

Easy handling.

- There is no pre-mix.

- Low levels of sound.

- Low price of servicing.

- The output is safe and simple.

- It is possible to disperse high viscous products.

- Economically, eat less material energy per liter.

The Wall Putty Plant Machinery Manufacture Fully Automatic Wall Putty Plant that we offer is produced in accordance with sector rules and comprises of a suitable diameter core pole. This equipment's core pole is equipped with particularly constructed propellers for counterflow intervention.

Wall Putty Plant Machinery Manufacture Semi Automatic Wall Putty Plant Exporter offers wall putty that is a cemented fabric that before painting is added to a coated ceiling. Putty's purpose: to insert on the stone layer any hairline cracks or pores. To produce a standardized, paint-ready layer smoothed out. To discourage or decrease the intake / absorption of water